LK 810 thermomat return increase

LK 810 thermomat return increase - 60 ° C is in stock and will be shipped as soon as it is available again

Delivery and shipping

Delivery and shipping

Processing time is typically 1 business day. Delivery for parcels is 1-3 business days. For freight forwarding, delivery time is 3-5 business days. Delivery times outside Germany vary.

Description

Description

ThermoMat return flow increase

Return flow increase 60°C or 70°C including insulation and 3 x 1¼" ball valve.

LK 810 ThermoMat 2.0 W is a return flow increaser for heating systems with solid fuel boilers and buffer storage tanks.

The Return flow increase is used to generate a high return temperature to the boiler and optimal temperature stratification in the buffer tank.

This increases the efficiency of the heating system, prevents condensation and tar deposits, and extends the system's service life.

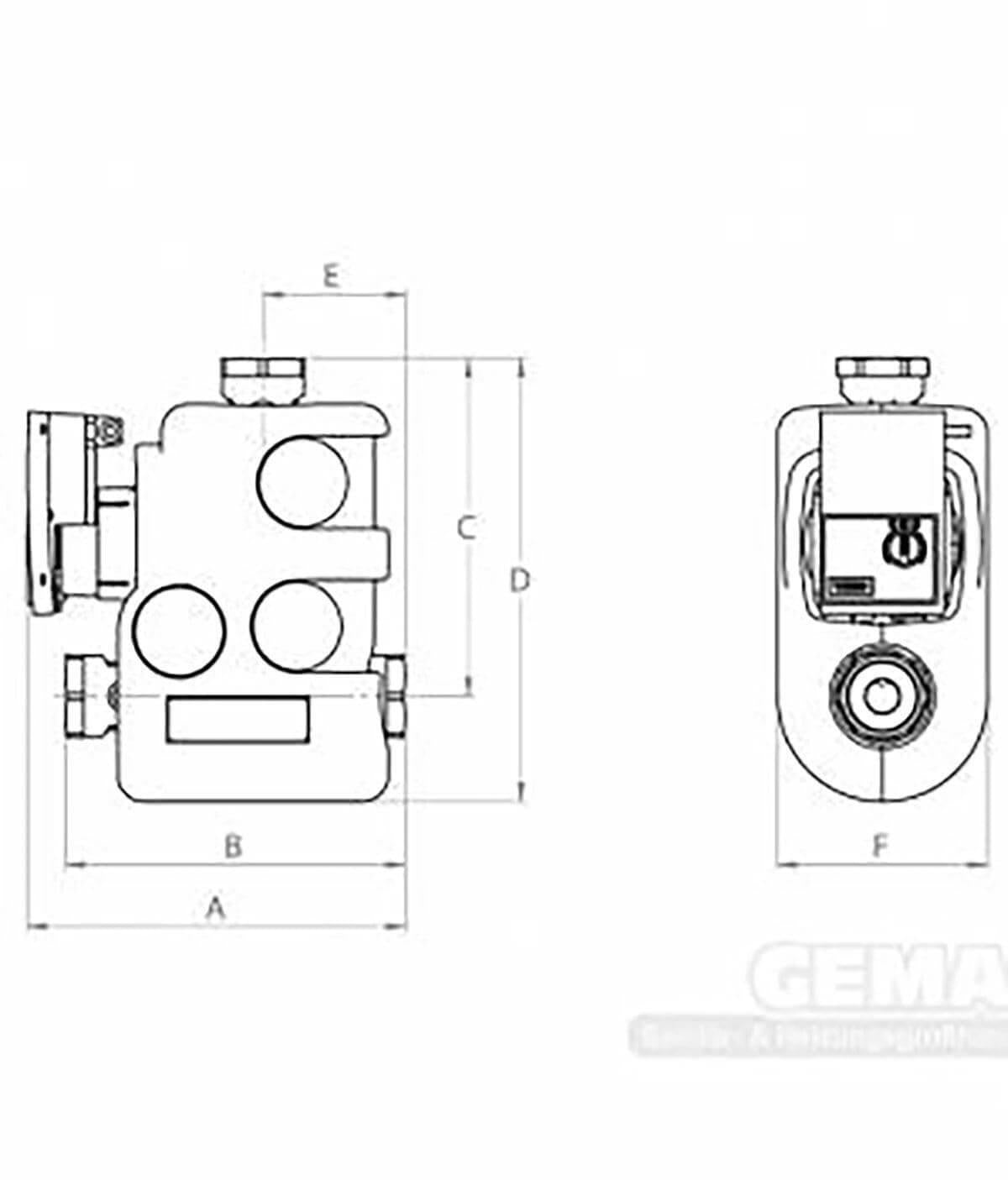

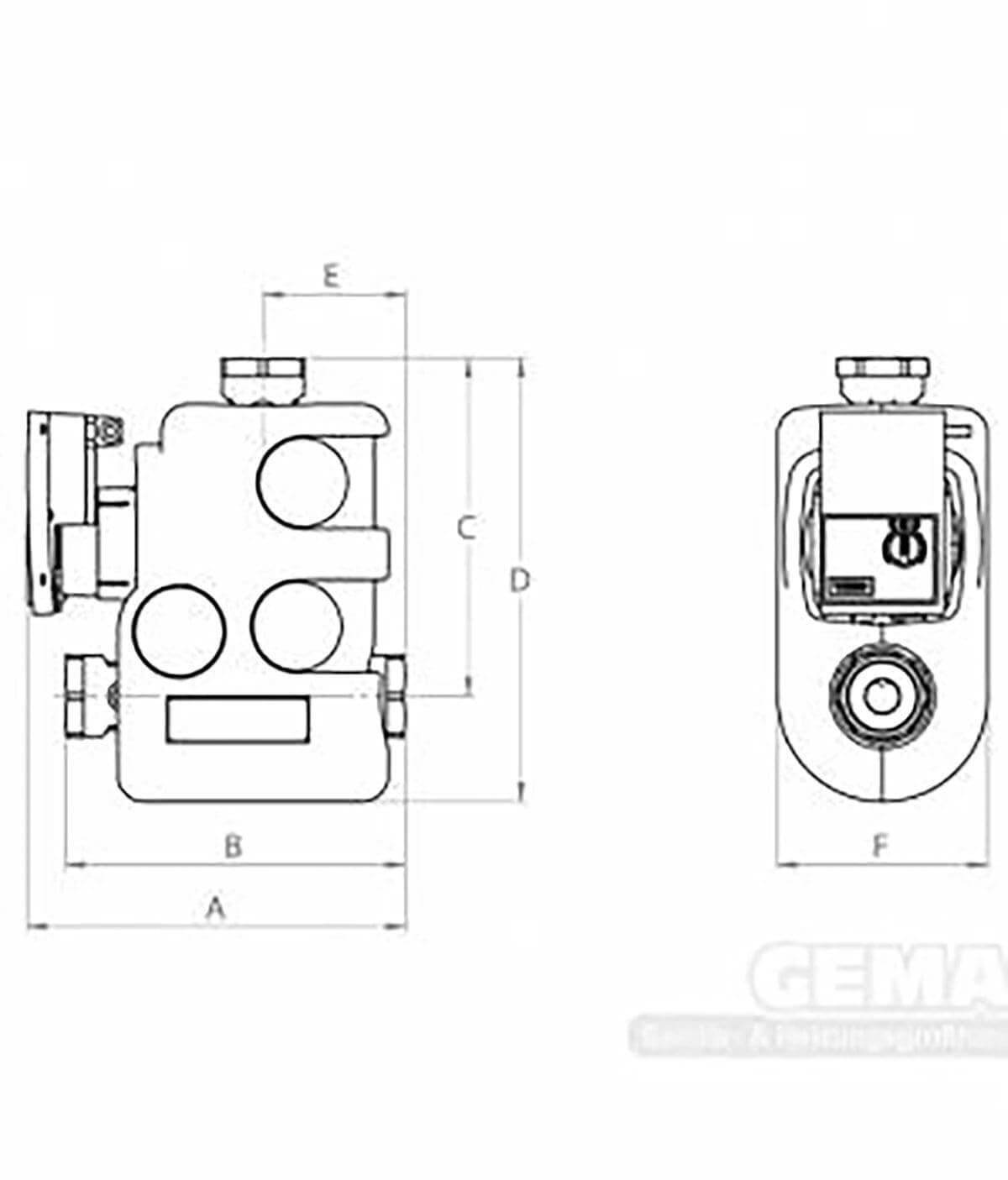

The LK 810 ThermoMat 2.0 W is a compact unit with an integrated high-efficiency pump and a thermal valve that controls two valve connections.

The Return flow increase has three shut-off valves to facilitate installation and maintenance, three thermometers that allow easy tracking of the charging process, and insulation to minimize heat loss.

LK 810 ThermoMat ThermoMat return flow increase 2.0 W is also available with a high-efficiency pump controlled by a PWM signal. For further information, please contact our sales department.

The LK 810 ThermoMat 2.0 W is installed in the return line between the solid fuel boiler and the buffer tank. It must be mounted vertically with the pump drive shaft in a horizontal position. The return flow booster is reversible and can be easily adjusted for installation on the right or left of the boiler.

The Return flow increase is normally maintenance-free. The installation should be inspected regularly. Thanks to the shut-off valves, all parts are replaceable without having to drain the system during maintenance.

*Technical changes reserved | Images may vary

payment & Security

Payment options

Your payment information is processed securely. We do not store or access your credit card information.