Termoventiler

Suitsugaasi termostaat 50-300 ° C pumba automaatseks juhtimiseks

Tavaline hind 51,86 €PõhihindEi ole saadavalPiiratud laos- Kuni 10% allahindlust

Sunex

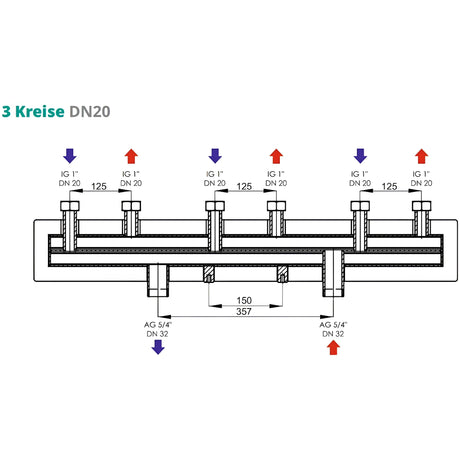

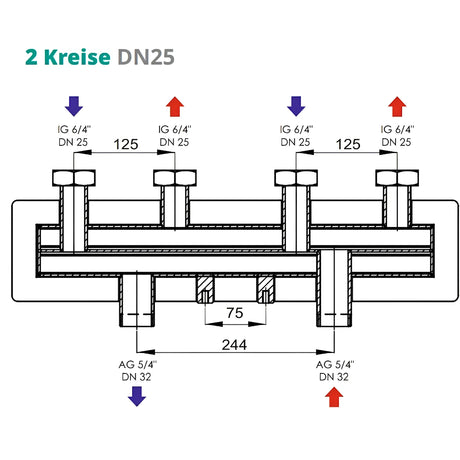

Jaotusriba 2 või 3 kütteahelat SUNEX

Tavaline hindEemal 108,90 €PõhihindEi ole saadavalLaos Caleffi

Caleffi automaatne täiteklapp ja demineraliseerimisseade

Tavaline hindEemal 422,12 €PõhihindEi ole saadavalLaosKutzner & Weber

Tõmbepiiraja 012 RaRo/012 RaRo E - Kutzner & Weber

Tavaline hind 71,56 €PõhihindEi ole saadavalPiiratud laos

In the professional sector, standards, approvals and quality labels are also crucial. Materials often have to meet standards such as DIN, EN or special Ü marks in order to be used in commercial projects. Planners and installers also pay attention to material compatibility in order to avoid electrochemical corrosion or undesirable reactions between different materials. A clearly structured range makes selection easier and ensures safe, energy-efficient solutions.

Pipe systems

Pipe systems form the backbone of every heating installation. Common materials are copper, steel, stainless steel, plastic pipes such as PE-X, PB or multilayer composite pipes. Each material has specific advantages: copper offers high thermal conductivity and durability, steel is robust for high pressures, plastic is characterized by being corrosion-free and easy to process. The choice of pipe material depends on the application, budget, type of installation (freely laid, in screed, under plaster) and the requirements for flexibility and thermal expansion.

It is important to correctly dimension the pipes to avoid pressure losses and noise. Hydraulic balancing, correct installation and professional connections are prerequisites for energy-efficient heat distribution. In addition, compatible pipe clamps, fixing material and protective tubes must be taken into account for bushings in order to minimize mechanical loads and reduce heat losses.

Connection technology and fittings

The connection technology includes plug-in, press-fit, clamp and screw connections as well as welding and soldering processes. Press fittings are particularly common in the plumbing and heating sectors as they enable fast, tight and reproducible connections. Screw and flange connections offer ease of service for larger components, while welded and soldered connections ensure maximum sealing and strength. The quality and workmanship of the fittings have a direct influence on the operational safety of the system.

When selecting the fittings, it is important to pay attention to the same material or compatible material combinations in order to avoid corrosion. In addition, suitable seals, washers and assembly tools are required to guarantee a long-lasting connection. Professional labeling and documentation of the connecting elements used make later maintenance and expansion work easier.

Valves and fittings

Valves and fittings control, shut off and regulate the flow in heating systems. These include shut-off valves, control valves, check valves, safety valves, drain valves and mixers. Quality, flow characteristics and tightness are crucial, as is the suitability of the material for the temperatures and media used. Thermostatic valves on radiators or control valves in heating circuits enable precise temperature control and make a significant contribution to energy efficiency.

Some fittings are equipped with special functionalities such as pre-settable flow limiters, integrated filter screens or flow-optimized interior designs to avoid hydraulic problems. When planning, accessibility for maintenance and replacement must be taken into account, as well as the possibility of retrofitting drives or sensors for automated controls.

Circulation pumps and hydraulics

Circulation pumps ensure the transport of heating water through the system and thus have a significant influence on the energy consumption of a system. Modern high-efficiency pumps with electronic speed control adapt their performance to actual requirements and thus save energy.Selection criteria are delivery height, flow rate, size, controllability and noise development. In multi-boiler systems or complex hydraulic systems, frequency converters or differential pressure controllers are used to ensure stable operating conditions.

The correct pump design requires knowledge of the pipe network, heating load and pump characteristics. In addition, attention must be paid to the assembly design, decoupling against vibrations and easy service accessibility. In many systems, a filter or dirt separator is also installed to extend the service life of pumps and fittings and to reduce deposits in the system.

Expansion vessels and safety components

Expansion vessels compensate for changes in the volume of the heating water due to temperature changes and thus prevent pressure fluctuations. Safety valves protect against overpressure and are required by law for many systems. Pressure monitors, pressure gauges and drain valves complement the safety equipment and support safe operation. The correct dimensioning and positioning of these components is essential to avoid damage caused by overpressure, cavitation or air accumulation.

Regular checking of the pre-pressures of expansion vessels, testing of safety valves and monitoring of system pressures are part of system maintenance. Spare parts and tested safety components should be permanently available, as failures in this area can quickly lead to expensive repairs or hazards. High-quality components with suitable connection dimensions simplify replacement and commissioning.

Control technology and sensors

Modern control technology includes thermostatic actuators, central control devices, room thermostats, weather controls, temperature sensors and smart controls. Precise control optimizes fuel consumption, increases comfort and reduces wear. Networkable systems enable remote monitoring, fault diagnosis and time-controlled programs. The prerequisite is professional coordination of sensors, actuators and control algorithms as well as clean cable routing and reliable power supply of the components.

When selecting the control technology, compatibility with existing systems must be checked. Openness to interfaces such as Modbus, KNX or proprietary protocols can make integration into building management systems easier. Good usability, intuitive user interfaces and documentation are an advantage for operators and maintenance personnel, as is the possibility of later expansion with additional sensors or functions.

Radiator accessories and connection sets

Radiator accessories include connection sets, thermostatic valves, vent valves, blind plugs, wall brackets and pipe insulation for radiator connections. A wide range enables individual solutions for different types and connection types. Connection sets make assembly easier and reduce installation errors because they are usually coordinated with one another and contain suitable seals and fasteners. Quality accessories ensure visually appealing, tight and service-friendly connections.

When replacing radiators, it is important that spare parts and connection variants are available. Compactness, easy disassembly and the ability to replace valves without emptying the entire system make maintenance work easier. Attractive and corrosion-resistant components also contribute to acceptance by the end customer.

Insulation and pipe insulation

Heat losses along the pipes significantly reduce the efficiency of a heating system.Pipe insulation made of closed-cell foam, mineral wool or special composite materials minimize heat loss, prevent condensation and reduce noise transmission. It is important to adapt the insulation thickness to the flow temperature and to take fire protection and vapor barrier requirements into account in buildings. Consistent and professional insulation makes a significant contribution to energy savings.

When selecting insulation materials, resistance to moisture, aging resistance and ease of processing are relevant. Also important to note are dimensionally stable protective caps, edge protection on bushings and suitable adhesives or clamps for fixation. Good documentation of the insulation measures helps with later inspections and repairs.

Fastening material and assembly aids

Robust fastening materials such as pipe clamps, brackets, support systems, threaded rods and dowels are necessary to securely fix cables. The selection depends on pipe weight, static load, installation environment and vibration sensitivity. Corrosion-resistant materials such as galvanized steel or stainless steel increase the service life, especially in damp rooms or unprotected outdoor areas. Clean fastening prevents sound vibrations and mechanical stress on connections.

Assembly aids such as laser distance measuring devices, pipe bender, cutting tools, bending devices and special adapters make quick and precise work easier. Investments in high-quality assembly tools pay for themselves through less rework and faster assembly times. Small parts such as washers, nuts and matching screws should also be available in sufficient quantities to ensure smooth assembly processes.

Seals, adhesives and corrosion protection

Sealants, O-rings, thread sealing tapes, assembly pastes and special adhesives are crucial for tight connections and long-lasting connections. Depending on the material and application, different sealants such as PTFE, NBR or EPDM are suitable. Solvent-free adhesives that are temperature and pressure resistant are used for adhesive connections and plastic systems. Corrosion protection coatings and sacrificial anodes protect metallic components from harmful reactions and extend the service life of the system.

The correct selection and processing of sealing materials prevents leaks and reduces the risk of water damage. Tested products with appropriate approvals must be used for critical applications. Also important is the compatibility of the sealants with the media and temperatures used in the system in order to avoid embrittlement or chemical decomposition.

Planning, standards and maintenance

Thoughtful planning forms the basis for a functional, economical heating installation. Hydraulic balancing, selection of suitable components, consideration of standards and the creation of detailed documentation are essential. Standards and regulations define safety requirements, test intervals and material properties that must be adhered to during project planning. Forward-looking planning makes later expansions and modernizations easier.

Regular maintenance, inspections and the use of replacement components from the same quality environment ensure high system availability. Maintenance contracts, spare parts stocks and documented test protocols help to minimize downtime. Selecting easily accessible and modular components makes repairs easier and reduces operating costs in the long term. Well-planned installation material is an investment in reliability, efficiency and sustainability.